9.1. Introduction.

Mr Simon Ogwal, a pig farmer got the interest to engage in pig production as a result of my exposure to the challenges faced by pig farmers in Nakaseke and Nakasongola district in the cattle corridor of Uganda. The challenge communities were facing in piggery production were poor breeds; traditional feeding and husbandry practices; infestation by worms and poor disease management; although the demand for pork and other pork products is rapidly expanding.

As a project manager at Africa Innovations Institute working for a Rockefeller Foundation funded project entitled “Securing livelihoods in the cattle corridor of Uganda”, I was part of a team tasked with the duty of identifying a climate smart technology that could be adapted to the situation in the cattle corridor and use it to boost pig production as one of the strategies to realize food and income security. A literature review exercise zeroed on the Deep Liter System (DLS) also commonly known as Fermented Bed Technology (FBT), a technology used by South Koreans. We introduced and piloted the technology with farmers in Nakaseke and Nakasongola districts. We started in 2013.

In order to walk the talk and put my money where my mouth is, I made the decision to introduce the same technology on my farm at the same time it was being introduced in the project area. I wanted to share my knowledge and experience with the farmers first hand and motivate them to embrace the technology.

To start piggery production using FBT, I made plans to acquire more information about the technology, search for locations where it was being used and draw a business plan to start commercial pig production. I used the internet google search engine to learn about FBT and visited a nearby demonstration site in Mukono town to familiarize myself with the blueprints of the housing structure. Then I consulted my animal production specialist friend about pig production and sought his consent to provide technical backstopping once the plan fell in place. Fortunately, he agreed to help me since he was also engaged in the same enterprise.

9.2. Starting the enterprise.

Before I could begin the enterprise, I put my mind in the position of an entrepreneur who was presented with an opportunity for funding in pig production and all that one needed was a winning business proposal. I used this approach because my business partner wanted a written document to justify our decision to invest part of the proceeds from the tree seedling business to pig production.

I prepared a 15 page business proposal containing information about the current state of pig production in Uganda, a SWOT analysis of the pig value chain in Uganda, details of FBT (breeds, feed management, structure, IMO, bedding materials, advantages and benefits of FBT) and its costs, projected cash flow under different production scenarios and a logical framework. I shared the proposal with my partner who has a background in financial accounting and auditing. I also shared it with a friend who has a background and experience in agricultural economics. After carefully reviewing and making some changes to the proposal, my partner gave the green light for the enterprise to begin.

9.3. Executing the proposal.

9.3.1. Identifying breeder stock and building FBT structure.

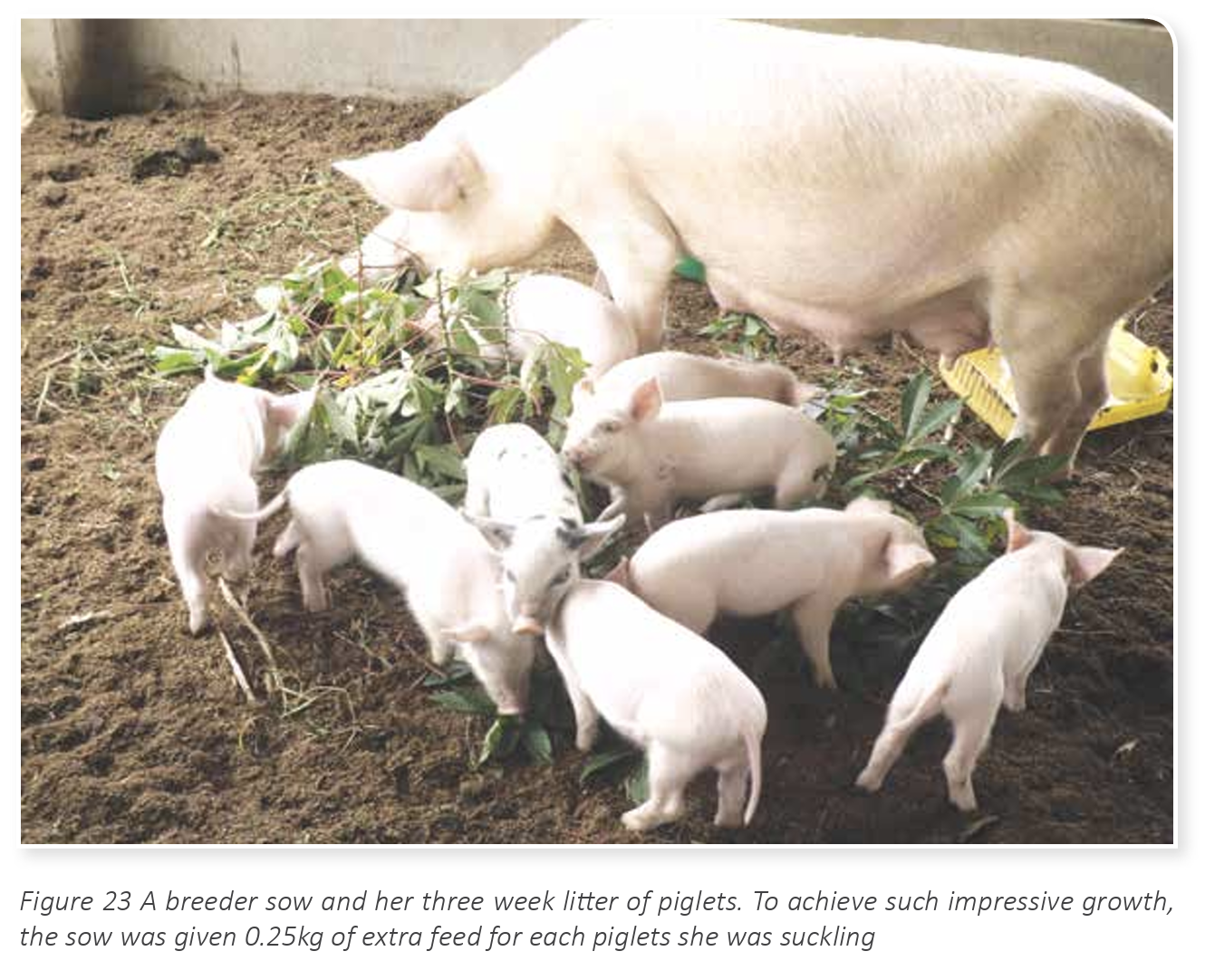

Using the same contacts that supplied breeding Sows for the Securing Livelihoods project, I was able to identify four two- months pregnant Sows to begin with as our breeding stock. Each Sow’s history was looked at in order to select the Sows with excellent mothering qualities, having at least 12 teats and whose liter survival after three weeks was 90%. A crossbreed of Landrace and Comborough was selected. Once booking was made, I started excavating four pits at my farm in Bukerere-Seeta, Mukono district. Each pit that was dug to a depth of 100cm was meant to house one Sow and her liter of 7-12 piglets up to weaning. A wall was erected around each pit, plastered and support columns erected to provide one roof over the four units (Figure 1).

9.3.2. Cost of constructing one unit.

Table 1 below gives cost of erecting one unit of the housing structure. Structures built using clay bricks last longer and provide better protection for the animals, so we decided to go for that.

9.3.3. Preparing and fermenting the bed.

When the walls of the units were plastered, we filled the pit up to 70cm with different bedding materials as follows: dry maize stalk up to 30cm, mixture of 60 bags of fine saw dust - (excluding that from pine tree) with100kg of red soil, 10Kg of builder’s lime and 10Kg table salt making up the remaining 40cm. Then we cultured a solution containing indigenous micro-organisms (IMO) for 6 days (Fig 20). To culture the IMOs, I made up 200 liters of water in a plastic drum, added 20 tablespoons of solid IMO, and 5 kgs (or scooped 40 handfuls) of pure maize bran to the drum and stirred the mixture thoroughly until a uniform suspension was achieved. I covered the drum with a mosquito net to protect it from insects and contamination. I incubated the mixture for seven days.

On the seventh day, I sprinkled 150 liters of the liquid IMO on to the litter and thereafter mixed and turned it thoroughly using a combination of hoes and garden forks. I only mixed the first 30cm of the litter with the liquid IMO until a moisture content of 60% was achieved. I did this daily for 10- 14 days before the breeding Sows were introduced. Fermenting the bed for two weeks was meant to raise the temperature of the bed to 600C. This temperature was needed to provide warmth to the sow and her liter and also enhance the activity of microbes in the bed. I kept the balance of 50 liters of IMO in the plastic drum as a starter culture for future use as and when necessary. We repeated treating the bed with IMO weekly as advised by the experts.

9.3.4. Introducing the breeding Sows.

I transported the breeding Sows from Gayaza Township to my farm early in the morning on a cool day. I had read that movement of the pigs on a hot and sunny day would make them die from heat stroke. I ear-tagged each sow with a plastic ear tag for easy identification and record keeping. My Veterinary doctor also injected them with iron and multivitamins. I introduced the Boar six months later to continue production.

9.3.5. Capacity building.

I used the period between delivery of the pregnant Sows and time of their littering to acquire as much information as I could regarding FBT and trained farm workers about management of bedding material, pregnant Sows, piglets, feed and feed management and record keeping.

9.3.6. Production of piglets.

After one month on the farm, the four Sows produced liters at different times. This occurred because the farmer who sold them did not keep records of date of serving. The records of the liter size are indicated in Table 2a-c above.

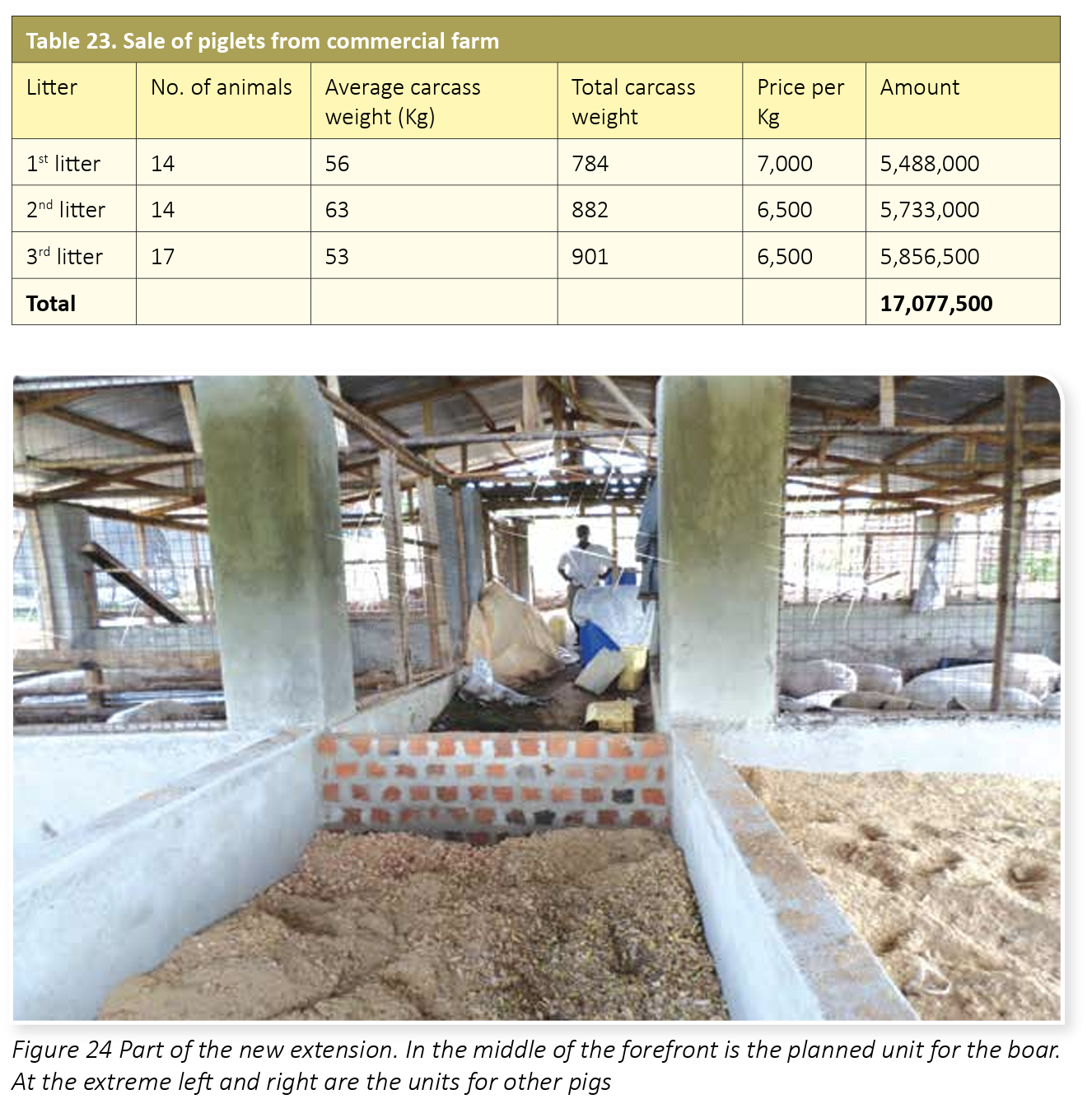

9.3.7. Sales.

All the males were castrated for easy management and sold as indicated in the table below. I got about UGX seventeen million. Some of the proceeds from the above sells were used for expansion of housing structures and introduce water nipples in some units. Three more units were built (Fig 5) to house a boar and more pigs as the business grew. I can pride myself of this money every six months. That is why I love pigs and shall devote my life for them.

9.4. Challenges which I met.

At school I was told that there is no business without challenges. Therefore for this business, I had to encounter and deal with a lot of challenges since I started operating it two years ago. The main challenges I faced are outlined below.

9.4.1. African Swine Fever (ASF) outbreak.

Ever since I started operating this farm in 2014, I had witnessed no ASF outbreak except January 2016 where it claimed a breeding boar and three pregnant Sows. I was devastated but I had no option but to accept the loss and prevent any further happening of the same. It is hard to pin point the source of infection because the bio-safety protocols at the farm are high. A veterinary officer and the farm worker suspect the virus was introduced by flies found on intestines of an infected pig slaughtered in the neighborhood. I think I sustained minimal loss at the farm because all my pigs live in different compartments in the housing structure.

We also maintain foot baths at the entrance of each unit to minimize chances of disease introduction to the units. To stop the spread of the virus, I suspended the inclusion of all animal proteins in our pig feed formula. We also stopped including silver fish in our feed formulation. We replaced these with palm kennel and ground roasted soya flour. We also sprayed the walls of the units with VIRUKILL to kill off any viruses.

9.4.2. High cost of feeding.

At the start of the business, the cost of feeds were high because a high proportion of the animal feed formula constituted maize bran (up to 70%). The cost of maize bran is variable depending on the season. In 2014, maize bran was readily available and cheap but from the beginning of 2015, the availability of maize bran was inconsistent and the price kept soaring.

According to feed mill operators, the price of maize bran is soaring because well-established maize dealers from Kenya and South Sudan are exporting whole maize grain to these respective countries. Without any value addition done in the country, there is no maize bran left for the animal industry in the country.

We had to find a cheap alternative source of carbohydrates to reduce the proportion of maize bran in the feed formula. We chose to use wheat bran and included it in the new fatteners feed formula. There are more than five wheat processing facilities in Kampala. The proportion of maize bran is now 11% while that of wheat bran is 64%. The other ingredients (silver fish, white and brown salt, shells, cottonseed cake and premix) are included as well, but in different proportions depending on the stage of growth of the pig.

The other alternative feed given to the Boar and Sows is brewer’s waste (spent yeast grain) bought from a local brewery located at the source of the Nile in Jinja. It is a cheap feed intended to prevent the Sows and Boars from getting obese. The pigs are also given sour milk to drink daily. Two liters of sour milk are mixed with three liters of water.

9.4.3. Tiresome routine of providing clean water.

The farm worker was always troubled about the task of giving large volumes of water to the ever-expanding pig population. To solve this challenge, the farm installed automated water nipples in six of the nine units.

9.4.4. Marketing farm products.

The market for pork in Uganda is very segmented and challenging. We conducted a market feasibility survey to identify and quantity the potential market for the pigs. Two abattoirs and three pork processing facilities were identified. I made contact with each of them to acquaint myself with their volume, procurement, distribution, payment and quality control terms and conditions. The farm is making arrangements to meet all the terms and conditions of at least one pork processing facility. All the pigs are currently being slaughtered at one abattoir and the carcasses sold to middlemen who distribute them to major hotels, restaurants and retail outlets (pork joints). Compost after fermenting the beds is sold to nearby farmers. We also use some to fertilize our banana plantation.

9.5. Future plans.

FBT is an excellent technology for pig production. We at the farm plan to continuously expand our operation, apply for a license to operate a slaughter slab so that it can supply good-quality carcasses to pork processing outlets. The long term plans involve making pork sausages and training interested farmer groups in pig production using fermented bed technology.